| API 598 Valve Inspection and Testing.pdf |

|

For the inspection, please be aware some of customers that they will ask their inspection company to attend all the tests which will be done to the valves especially the hydrostatic tests. As a professional manufacturer, we should supply all documents likely materials test report, hydraulic pressure testing report and so on. And the pressure testing report will be made according to API 598 if the valves are designed according to ANSI/API standard. The testing standard indicates the leakages level for different valves. The testing includes backseat Test, shell test, low-pressure closure test and high-pressure closure test.

0 Comments

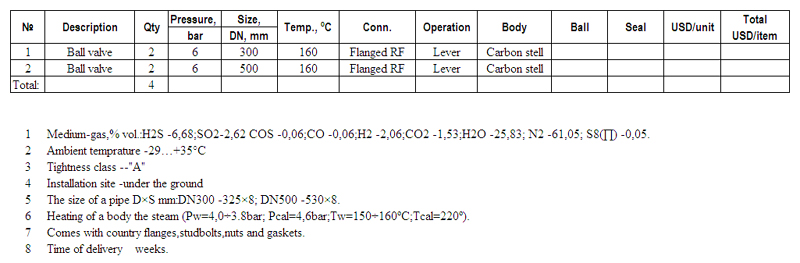

The below table is a ball valve enquiry from our customer. It is a sample. And it is no need to inform full information, but please try to inform the working situation so that we can make the choice. And please pay attention as below:

Valve Size : Nominal size of the pipeline into which the valve will be placed must be determined. Valve Material : The facts should be considered in determining the correct valve material, likely the medium, temperature range, pressure range, possible atmospheric conditions and extraordinary stresses, safety standards and or piping code etc. Valve Type : What is the control function of the valve? Gate valve, globe valve, check valve, ball valve, butterfly valve, plug valve etc. Pressure-Temperature Ratings : Please pay careful attention that the pressure-temperature ratings of a particular valve are in keeping with the requirements of the service. Also please pay attention to the packing and gasket materials as necessary to meet or exceed your service requirements. Valve and Connections : Considerations as to pipeline integrity, future maintenance, corrosion factors, field assembly, weight and safety should be given in determining the method of connecting the valve in the pipeline. Method of Operation : The means by which the valve is operated as supplied are shown for the valves in this catalog. Many optional operating devices are regularly supplied by us. Talking about the valve trim, the internal elements of a valve are collectively referred to as the valve trim. The trim typically includes a disk, seat, stem, and sleeves needed to guide the stem. A valve performance is determined by the disk and seat interface and the relation of the disk position to the seat. Because of the trim, basic motions and flow control are possible. In rotational motion trim designs, the disk slides closely past the seat to produce a change in flow opening. In linear motion trim designs, the disk lifts perpendicularly away from the seat so that an annular orifice appears.

API 600 TRIM NUMBER CHART Trim # Seat Disc Backseat Stem 1 410 410 410 410 410 2 304 304 304 304 304 3 F310 310 310 310 310 4 Hard 410 Hard 410 Hard 410 410 410 5 Hardfaced Stellite Stellite 410 410 5A Hardfaced Ni-Cr Ni-Cr 410 410 6 410 and Cu-Ni Cu-Ni 410 410 410 7 410 and Hard 410 Hard 410 Hard 410 410 410 8 410 and Hardfaced Stellite 410 410 410 8A 410 and Hardfaced Ni-Cr 410 410 410 9 Monel Monel Monel Monel Monel 10 316 316 316 316 316 11 Monel and Hardfaced Stellite Monel Monel Monel 12 316 and Hardfaced Stellite 316 316 316 13 Alloy 20 Alloy 20 Alloy 20 Alloy 20 Alloy 20 14 Alloy 20 and Hardfaced Stellite Alloy 20 Alloy 20 Alloy 20 15 304 and Hardfaced Stellite Stellite 304 304 16 316 and Hardfaced Stellite Stellite 316 316 17 347 and Hardfaced Stellite Stellite 347 347 18 Alloy 20 and Hardfaced Stellite Stellite Alloy 20 Alloy 20 Note: 410 material is the same as 13Cr or F6 trim. Welcome to visit our valve blog. We will offer you complete valve control solution if you have any questions.

|

Authorwelcovalve@gmail.com Archives

April 2019

Categories

All

|

RSS Feed

RSS Feed