|

In 2019, seawater butterfly valves are exported, we cooperated with a middle east customer for one project 72" watersupply pipeline. The fluid is seawater civil engineering. These valves are solid fully lugged, the body material ASTM A216 Gr. WCB, Disc is ASTM B148 C95400, Stem is duplex stainless steel material. From body & seat mould design mould to products delivery, it takes over three months. Finally, the inspection was highly accepted by our Kuwaiti customer.

0 Comments

What kind of butterfly valves can we supply?

As one of the most professional manufacturers in China, we design and manufacture for years. Cast Iron Butterfly Valve, Cast Carbon Steel Butterfly Valve, Cast Stainless Steel Butterfly Valve, Rubber lined Butterfly Valve, P.T.F.E. lined Butterfly Valve, Wafer Type Butterfly Valve, High Performance Butterfly Valve, Center Disc Butterfly Valve, Off-Set Disc Butterfly Valve, Gear operated Butterfly Valve, Pneumatic operated Butterfly Valve, Electrical operated Butterfly Valve, Zero Leakage Butterfly Valve, Double Flange Type Butterfly Valve, Bi-directional Butterfly Valve. Butterfly Valve Features: Concentric, Double Eccentric, Triple Eccentric Design Excellent Sealing Capacity Soft Seat / Hard Seat Design Lower Torque with any fluid Permanently tight closure Bi-Directional Valve Optimum operation under Vacuum Condition Suitable for On-off as well as Throttling Service Materials for almost all media Short / Long Face To Face Dimension Wafer, Lug, Double Flange, Butt-Weld Design Body Long Service Life Smooth, Easy Operation Maintenance Free Version Less Weight, Easy To Install Butterfly Valve Design & Testing International Standard: Valve Design: API 609, BS 5155, MSS SP-67, EN593, MSS SP-68, GB/T12238, AWWA C504 Pressure Testing: BS 6755-I, API 598, ISO 5208 etc Face To Face: ANSI B 16.10, API 609, DIN3202-K1, EN558-1 20 Series, BS5155, MSS SP-67 etc Flange Drilling: ANSI B 16.5, ASNSI B16.47, API 605, AWWA C207, BS 10 Table / DIN / IS / JIS Std. Pressure Rating: Class 150, Class 300, Class 600, Class 900 Leakage Class: Class VI (Zero Leakage) Size Range: DN50 to DN3000 (2” to 120”) Operation: Up to DN200 lever operated, and above gear operated. On special request available for electric, pneumatic and hydraulic operated. Butterfly Valve Material of Construction: Body: Cast Iron to ASTM A 126 Class B / HT200 / HT250; Ductile Iron to ASTM A 536 Grade 65-45-12 / GGG40, GGG50; Cast Carbon Steel to ASTM A 216 GR. WCB / A352 LCB / LCC; Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M; Alunium Bronze ASTM A148 B95500, C955800 Disc: Cast Iron to ASTM A 126 Class B / HT200 / HT250; Ductile Iron to ASTM A 536 Grade 65-45-12 / GGG40, GGG50; Cast Carbon Steel to ASTM A 216 GR. WCB / A352 LCB / LCC; Stainless Steel to ASTM A 351 GR. CF 8 / 8M / 3 / 3M; Aluminium Bronze ASTM B 148-C95400; Nylon Coating on C.I. / D.I. / WCB / S.S. Disc Material; EPDM / Neoprene / Hypalon / Nitrile Rubber / Buna-N; Rubber Encapsulated on C.I. / D.I. / WCB / S.S. Disc Material; P.T.F.E. (PFA / FEP) Lined on C.I. / D.I. / WCB / S.S. Disc Material Seat (Liner): EPDM; EPDM Food Grade; Buna-N; Black Nitrile; Neoprene; Hypalon; Silicon; Viton; P.T.F.E. Stem: AISI 410 (S.S. 410, 13% Cr. Steel); AISI 304 (S.S. 304); AISI 316 (S.S. 316); AISI 304L (S.S. 304L); AISI 316L (S.S. 316L); 17-4PH, Monel K400 / K500 Test Specification: Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test. Seat Test: 1.5 times the working pressure with water. Function / Operation Test At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc. Special Test On request, any other test can be carried out according to special instruction by client Butterfly Valve Applications: Water Treatment Plant, Paper Industry, Sugar Industry, Breweries, Chemical Industry, Waste Effluent Treatment Plant, Drilling Rigs, Gas Plant, Cooling Water Circulation, Heating & Air Conditioning, Pneumatic Conveyors, Compressed Air Please specify below details while you have enquiries/orders: 1.Types of Valve; 2. Pressure Rating Class; 3. Valve Size; 4. Type of End Connection; 5. Material of Construction; 6. Disc Material; 7. Rubber Seat Material; 8. Flow Medium (Service); 9. Design Pressure; 10. Operating (Working) Pressure; 11. Design Temperature; 12. Operating (Working) Temperature; 13.Type of Operation Manual / Pneumatic / Electric etc. Chinese Valve Production has Over 2.6 Million Tons from January to May in 2012

In recent years, Chinese valve industry has entered a period of rapid development, has become Asia's largest valve machining center, one of the world's largest valve market. The monitoring data shows from January to May in 2012, the valve output reached 2.629 million tons in China, it has an increase of 14.64%. In May, the chinese production of valves 609,300 tons, an increase of 7.40%. From the production point of view of provinces and cities, from January to May in 2012, the largest valome of our chinese valve production comes from three provinces and cities in Zhejiang Province, Henan Province and Jiangsu Province, respectively, accounting for 28.88% of the total output, 22.36% and 13.88%. The per capita consumption level of our valve products in the world and not high, currently only $ 22 per capita. With the development of the valve industry in China, the varieties of valves are constantly more and more, the application of the valve industry, such as the petrochemical industry, oil refining industry, nuclear industry, thermal power industry has widely used, indicating that the prospects broad market attractive. The Competition Analysis of Chinese Valve Industry in 2011-2012

Global valve manufacturing focused on the economically developed regions of North America, Europe and Asia, Japan, China and other regions. Ranked global valve manufacturing industry, the top five were: the United States, Japan, Germany, China and the United Kingdom. Among them, the U.S., Europe and Japan and other developed countries and regions, mainly in the metallurgical, petrochemical, nuclear power valve, lower production and sales ratio to the drain valve. In recent years, demand-pull impact to the drainage valve market faster growth areas, including China, India and other countries, including East and Southeast Asia. Domestic point of view, our valve business volume highest in the world, but at the same time, the domestic to the overall size of the drainage valve business too small, industry concentration is not high, the size and financial strength is difficult to compete with large foreign companies. Valve Branch of China General Machinery Industry Association statistics show that in the first half of 2009, as of the end of June 2009, the main business of the semi-annual sales volume of China's major water supply and drainage valve business in 300 million yuan. An Outlook for the Development of Water Drainage Valve in 2012-2013

(1) market overall demand continued to maintain steady growth Mechanical processing and manufacturing, to the water valve manufacturing industry and its market development is mainly affected by the stimulating effects of the downstream application market. According to statistics of China General Machinery Industry Association, the world's total demand for the types of valves, industrial valves, including about $ 60 billion, of which approximately $ 6.84 billion to the water valve. With the growing demand of developing countries on the control valve, and environmental protection valve, to the water valve industry is expected to remain stable growth. From the perspective of the domestic situation, the infrastructure is the focus of China's economic construction, water supply and drainage in size, since the global economic crisis, the state increase its infrastructure investment, water treatment equipment manufacturing industry has been formed, including water supply and drainage valves water industry, provide a huge space for development of the drainage valve industry. (2) large diameter, large diameter valve market, domestic production capacity, market demand With the constantly increasing rate of urbanization in China, urban population growth, the scale of the supply quantity of the water plant and sewage treatment plants and sewage treatment is to gradually increase the caliber of the pipe network is increasing and therefore require a large number of various types of large diameter, large diameter drain valve door. At the same time, into the water conservancy construction and management of various types of flood control, drainage, irrigation, water supply and drainage, hydroelectric power, water and soil conservation, water conservation and other works of construction is very strong demand for all types of large diameter, large diameter water supply and drainage valves, resulting in At present, large-caliber and large caliber to the drain valve capacity production can not meet the downstream market demand growth. The next few years, China continues to accelerate the implementation of comprehensive management of a new three projects of the Huaihe River and Taihu Lake, Dongting Lake, Poyang Lake, and promote key sections governance of Ningxia and Inner Mongolia reaches of the Yellow River, Yangtze River middle and lower reaches of the river regime control major rivers, "South Water Transfer to North” project of the century the launching of the project will continue to boost the scale of demand for products of various types of valves, especially in large diameter valve, large triple offset butterfly valve, large diameter turbine inlet valve, large diameter flow control valve and the varieties of the large diameter vacuum valve. Due to the large diameter and large diameter valve production on the technical and technological requirements to be much higher than normal valves, a single product with higher added value, a higher demand this level of product design and processing level. Currently, only some of domestic enterprises can meet the requirements for technology and equipment, most of the other companies in the industry to the production of normal small diameter valves, from the entire industry, the production of large diameter water supply and drainage valves production will appear in a steady growth trend. According to take intermediate values between the valve Branch of China General Machinery Industry Association statistics, large diameter and large diameter valves in the field of water supply and drainage, the share of sales accounted for approximately 50% to 60%, 55%, from 2009 to 2011 The size of the market was 82.4 billion yuan, 9.55 billion yuan and 10.58 billion yuan. A general overview of worldwide valve industry in 2012

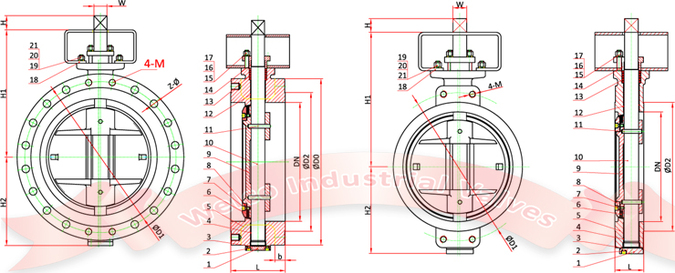

Valve is widely used in all major aspects of the national economy, energy, petrochemical, metallurgy, electric power and other industries. It is one of the key equipment in the equipment of machinery, pipelines and other fixed assets. Therefore, the development of valve industry is relative with macroeconomic cycles as well as investment in fixed assets. Since 2000, the global economy steadily recovering since the trough, according to IMF statistics, in 2001-2007 the average annual global GDP growth of 4.04 percent average, annual global investment in fixed assets grew by 3.72 percent. European industry forecast (European Industry Forecast Limited) "global valve market :2008-2013," Statistics, the compound annual growth rate of the finished valve sales revenue in the global economic up-cycle in 2002 and 2007 was 5.60%, to maintain steady growth of development. In 2008, the financial crisis began in earnest in the United States rapidly sweeping the globe, including Europe, North America, including the major economies are affected, global GDP growth rate dropped from 5.15% in 2007 to 3.2% in 2008 and 2009 -1.32%. The rapid cooling of the global economy, investment in fixed assets of the valve downstream industry had a certain negative impact, oil and gas, power, chemical and other industries have emerged to postpone the implementation of the phenomenon of fixed assets investment projects, the sound development of steady growth in the valve industry The momentum had a negative impact. According to market research company McIlvaine, the global valve industry in 2009 revenues of $ 47.436 billion, a growth rate of only 0.56%. The medium to long term, the main factors affecting the valve industry, the expansion of downstream industries, including the growing energy demand, the continued increase in global population and urbanization in developing countries, the process of industrialization and did not change fundamentally the result of the financial crisis. The world's major economies have entered the economic recovery cycle (according to IMF statistics and forecasts, 2010 and 2011 global economic growth have resumed their growth, the growth rates were 5.2% and 3.8% in 2012 - 2013 global economic growth rate is expected to remain above 3%). Valve industry since 2010, began to recover, according to a the McIlvaine survey and forecast data, 2010 and 2011, global valve industry revenues were $ 49,230,000,000 and $ 51,066,000,000, the growth rate back to 3.78% and 3.73% 2012 -2015 global valve industry expected sales growth will reach 4.16% and 3.93%, 3.94% and 4.18%, showing a steady upward growth. Please download our the below valve drawing for reference. It is metal hard seal, three eccentric design butterfly valve, available double flange, wafer type and lug type, as well as butt welded ends. It is just for technical evaluation if you have are interested in this products. Our design allows reduced torques and excellent throttling capabilities of the offset disc assemblies. The metal-metal seal assures a perfect tightness even at pressure and/ or temperature & pressure changes.

Materials: carbon steel WCB, LCB, LCC, LC1, LC3, stainless steel CF8, CF8M, CF3, CF3M, duplex steel 1A(CD4MCu) 2A(CE8MN) 3A(CD6MN) 4A(CD3MN) 5A(CE3MN) and aluminium bronze etc. Size range: DN50 to DN3000, 2" to 120" nominal diameter. Design standards: API 609, EN593, MSS SP-67, MSS SP-68, GB/T12238 etc Face to Face dimensions: DIN3202-K1, EN558-1 20 Series, BS5155, MSS SP-67 etc Design pressure: Pressure Rating ANSI Class 150#, Class 300#, Class 600#. Working temperature:-29 ºC to + 425ºC, Special materials can be from -196°C to + 600°C. End flange dimension: ASME B16.5 (for NPS not more than 24"), ASME B16.47 series B, API 605, ASME B16.47 series A (for NPS> 24"), or BS EN 1092. Operation: lever, worm gear, pneumatic, electric, hydraulic or pneumatic-hydraulic actuator. Charateristic: longer service life and available high temperature and pressure. Application: is widely used in oil refining, chemical machinery industries, chemical and petrochemical processing, water pipeline system etc. 1. API 609 Triple Offset Butterfly Valve Drawing Flanged 150LB DN100~DN600 2. API 609 Triple Offset Butterfly Valve Drawing Flanged 150LB DN700~DN1500 3. API 609 Triple Offset Butterfly Valve Drawing Wafer 150LB DN100~DN600 4. API 609 Triple Offset Butterfly Valve Drawing Wafer 150LB DN700~DN1500 5. API 609 Triple Offset Butterfly Valve Drawing Lug 150LB DN100~DN600 6. API 609 Triple Offset Butterfly Valve Drawing Lug 150LB DN700~DN1500  D343H butterfly valve is wormgear operated, double flange, three eccentric (triple offset) metal seal structure butterfly valve. The seal is in the form of metal to metal, metal seals can be composited stainless steel and graphite combined sealing. It can be available manual, electric, pneumatic, hydraulic actuators etc. D373H butterfly valve is wormgear operated, wafer type, three eccentric (triple offset) metal seal structure butterfly valve. The seal is in the form of metal to metal, metal seals can be composited stainless steel and graphite combined sealing. It can also be available manual, electric, pneumatic, hydraulic actuators etc. And please pay attention to the flow questions for D343H butterfly valve and D373H butterfly valve when the valves are working in project: 1, We know the sealing ring are graphite and stainless steel SS304 composited material that is fixed in the valve disc. The disc is normally open status, the media will crash the sealing surface at the front erosion of seal ring, this will affect the sealing performance. 2. the structural limit, usually it is not suggested for below diameter DN200 valve, because the overall structure of the disc is too thick and the flow resistance is large. 3. Due to the principle of eccentric structure, the sealing surface of the valve plate and valve seat seal on the transmission of torque to the valve plate pressure to the valve seat. When it is in right flow status, the pressure is higher, the sealing is tigher. But when it is in reverse flow medium with media pressure, the seal may start to leak when the reverse pressure is back to the disc. So some customers ask us to design it bi-directional seal for triple offset butterfly valve. Usually it is single direction seal if not requested by customer. D343H butterfly valve and D373H butterfly valve is widely used in water supply system, foodstuff, beverage, pharmaceutics, boiler, oil refining, chemical machinery industries, chemical and petrochemical processing, power generating plants, pulp and paper manufacturing processing, desalination, steelmaking, coal and mining industries. Size range from 2" to 120", pressure range from Class 150Lbs to Class 600Lbs. Chinese Valve Standards - Chinese standards for steel, cast iron and metal valves

GB12220: General valve - marking GB12221: Flanged ends metal valve - face-to-face dimensions GB12222: Multi-turn valve - connection of driving device GB12223: Part-turn valve - connection of driving device GB12224: Steel valve - general requirements GB12225: General valve - copper alloy casting ware technology requirements GB12226: General valve - gray casting iron technology requirements GB12227: General valve - ductile casting iron technology requirements GB12228: General valve - carbon forging steel technology requirements GB12229: General valve - carbon casting steel technology requirements GB12230: General valve - a casting steel technology requirements GB12232: General valve - flanged ends iron gate valve GB12233: General valve - iron gate valve and lift check valve GB12234: General valve - flanged and butt-welding ends copper gate valve GB12235: General valve - flanged steel stop and lift check valve GB12236: General valve - steel swing check valve GB12237: General valve - flanged and butt-welding ends steel ball valve GB12238: General valve - flanged and wafer ends butterfly valve GB12239: General valve - diaphragm valve GB12240: General valve - iron plug valve GB12241: Safety valve - general requirements GB12242: Safety valve - characteristic testing solution GB12243: Direct spring loaded safety valve GB12244: Pressure reducing valve - general requirements GB12245: Pressure reducing valve - characteristic testing solution GB12246: Pilot operated pressure reducing valve GB12247: Steam trap valve - classification GB12248: Steam trap valve - technology terms GB12249: Steam trap valve - marking GB12250: Steam trap valve - face-to-face dimensions GB12251: Steam trap valve - testing solution GB/T1392: General valve - pressure testing GB/T13932: General valve - iron swing check valve GB/T15185: Iron and copper ball valve GB/T15188.1: Valve face-to-face dimensions - butt-welding ends valve GB/T15188.2: Valve face-to-face dimensions - wafer ends valve GB/T15188.3: Valve face-to-face dimensions - female screw-down valve GB/T15188.4: Valve face-to-face dimensions - male screw -down valve BS Valve Standards

An overview of British Standard - BS - valve standards BS 1212: Ball valves (Portsmouth type ) excluding floats BS 1123: Specification for safety valves, gauges and other safety fittings for air receivers and compressed air installations BS 1414: Specification for steel edge gate valves ( flanged and butt- welding ends ) for the petroleum, petrochemical and allied industries BS 1552: Control plug cocks for low - pressure gases BS 1570: Specification for Flanged and Butt - welding ends steel plug valves for the petroleum industry (excluding well - Head and flow - line valves) BS 1735: Specification for Flanged cast iron outside - screw - and - yoke edge gate valves class 125, size 1.5 in to 24 in for the petroleum industry BS 1868: Specification for steel check valves (flanged and butt-welding ends ) for the petroleum, petrochemical and allied industries BS 1873: Specification for Steel globe and globe stop and check valves (flanged and butt-welding ends ) for the petroleum, petrochemical and allied industries BS 1952: Specification for copper alloy gate valves for general purposes BS 1953: Copper alloy check valves for general purposes BS 1968: Floats for Ball valves ( copper ) BS 2060: Copper alloy screw - down stop valves for general purposes BS 2080: Specification for Face - to - face, centre - to - face end - to -end and centre - to - end dimensions of flanged and butt-welding ends steel valves for the petroleum, petrochemical and allied industries BS 2591 PT.1: British standard glossary for valves and valve parts (for fluids ) part 1.screw - down stop ,check and gate valves BS 2591 PT.2: British standard glossary for valves and valves parts ( for fluids) part,2 safety valves and relief valves BS 2591PT.3: British standard glossary for valves and valve parts (for fluids ) part 3, Plug valves and cocks BS 2591PT.4: British standard glossary for valves and valves (for fluids ) part4, butterfly valves BS 2591PT.5: British standard glossary for valves and valve parts ( for fluids ) part5, Ball valves BS 2995: Specification for cast and forged steel wedge gate, glove, check and plug valves screwed and socket - Welding sizes 2 in and smaller for the petroleum industry BS 3464: Specification for cast iron gate valves for general purposes BS 3808: Specification for cast and forged steel flanged, screwed and socket - welding Wedge gate valves (compact design ) sizes 2 in and smaller for the petroleum industry BS 3948: Specification for cast iron parallel slide valves for general purposes BS 3952: Specification for cast iron butterfly valves for general purposes BS 3961: Specification for cast iron screw - down stop valves and stop and check valves for general purposes BS 4090: Cast Iron check valves for general purposes BS 4133: Flanged steel parallel slide valves for general purposes BS 4312: Flanged steel screw - down stop valves and stop and check valves for general purposes BS 4460: Steel Ball valves for the petroleum industry BS 5146: Specification for inspection and test of steel valves for the petroleum petrochemical and allied industries BS 5150: Cast iron wedge and double disk gate valves for general purposes BS 5151: Cast iron gate (parallel slide ) valves for general purposes BS 5152: Cast iron globe and globe stop and check valves for general purposes BS 5153: Cast Iron check valves for general purposes BS 5154: Copper alloy globe stop and check, check and gate valves for general purposes BS 5155: Cast iron and carbon steel butterfly valves for general purposes BS 5156: Screw down diaphragm valves for general purposes BS 5157: Steel gate (parallel slide ) valves for general purposes BS 5159: Specification for cast iron and carbon steel ball valves for general purposes BS 5160: Specification for Flanged steel globe valves, globe stop and check valves and lift type check valves for general purposes BS 5351: Steel ball valves for the petroleum petrochemicals and allied industries BS 5417: Test of genera purpose industrial valves BS 5418: Marking of general purpose industrial valves |

Authorwelcovalve@gmail.com Archives

April 2019

Categories

All

|

RSS Feed

RSS Feed